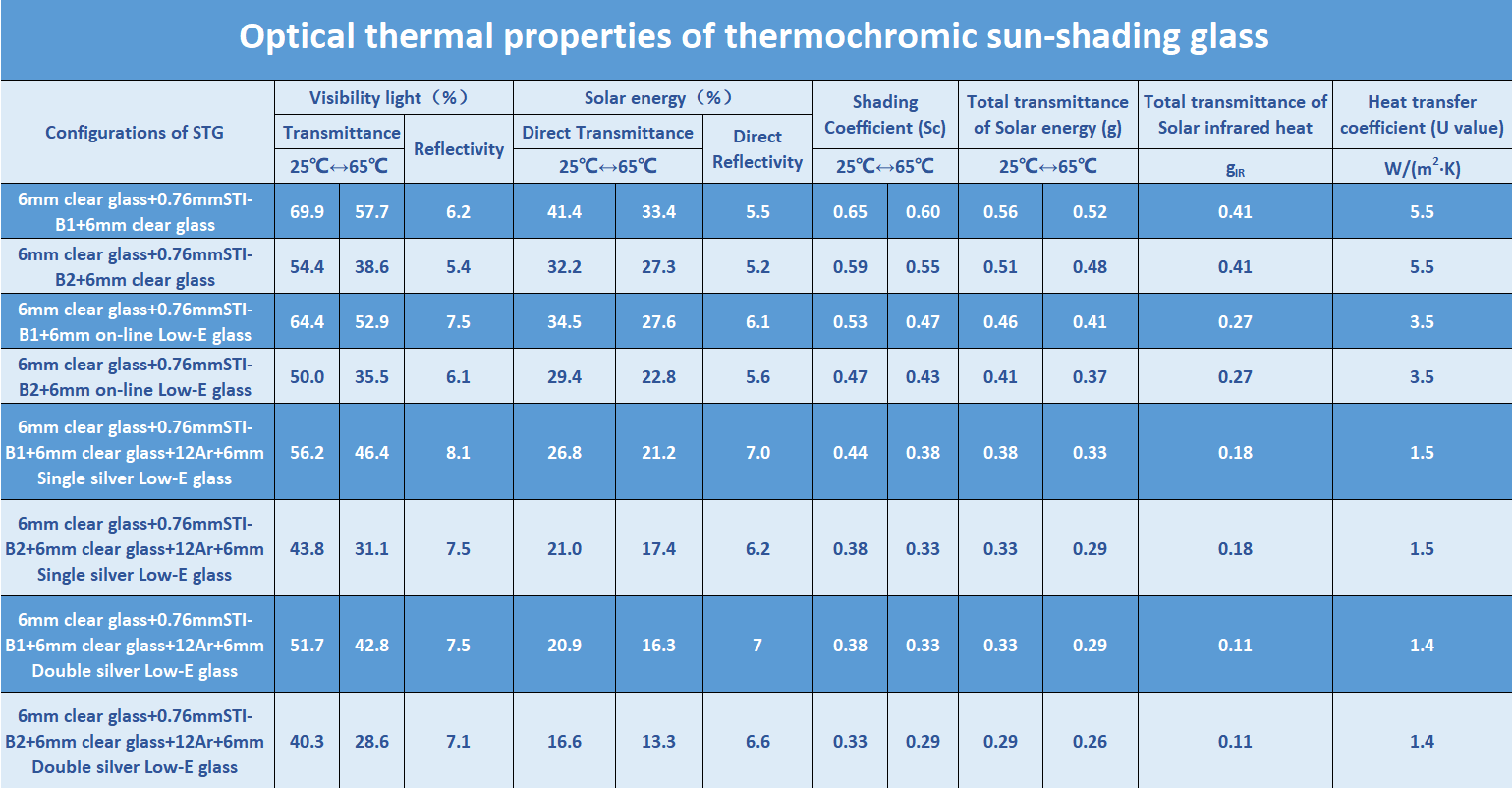

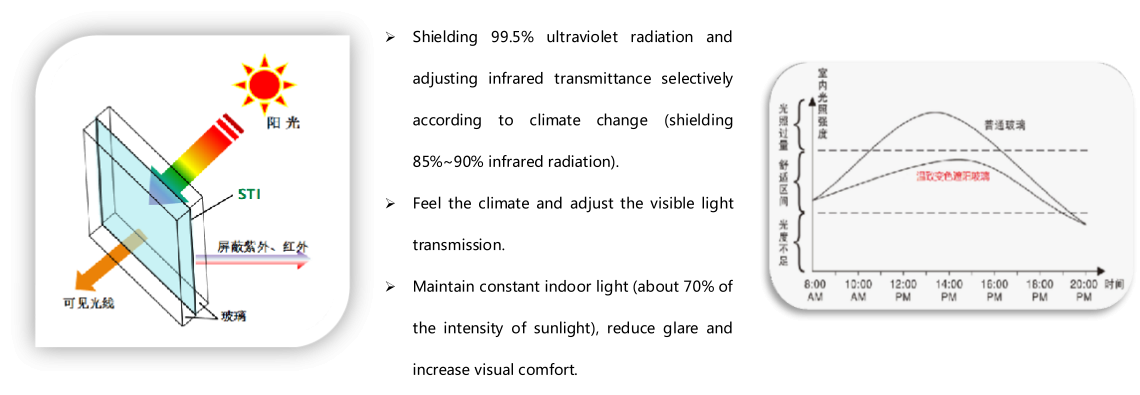

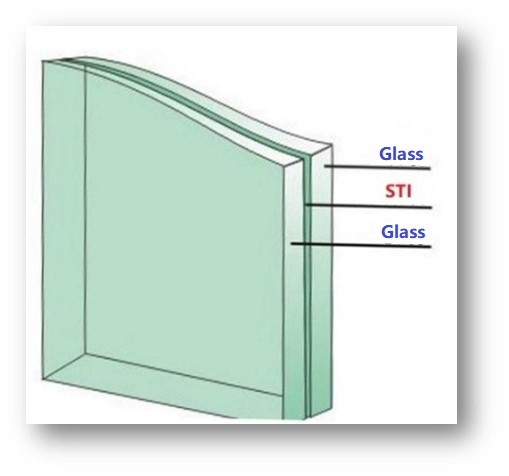

STI can be used for making thermochromic sun-shading glass (STG) by dry sandwich equipment, which can improve the performance and strength of glass obviously, and has the functions of intelligent color change, sun-shading, energy saving, safety, beauty, transparency, anti-glare and privacy.

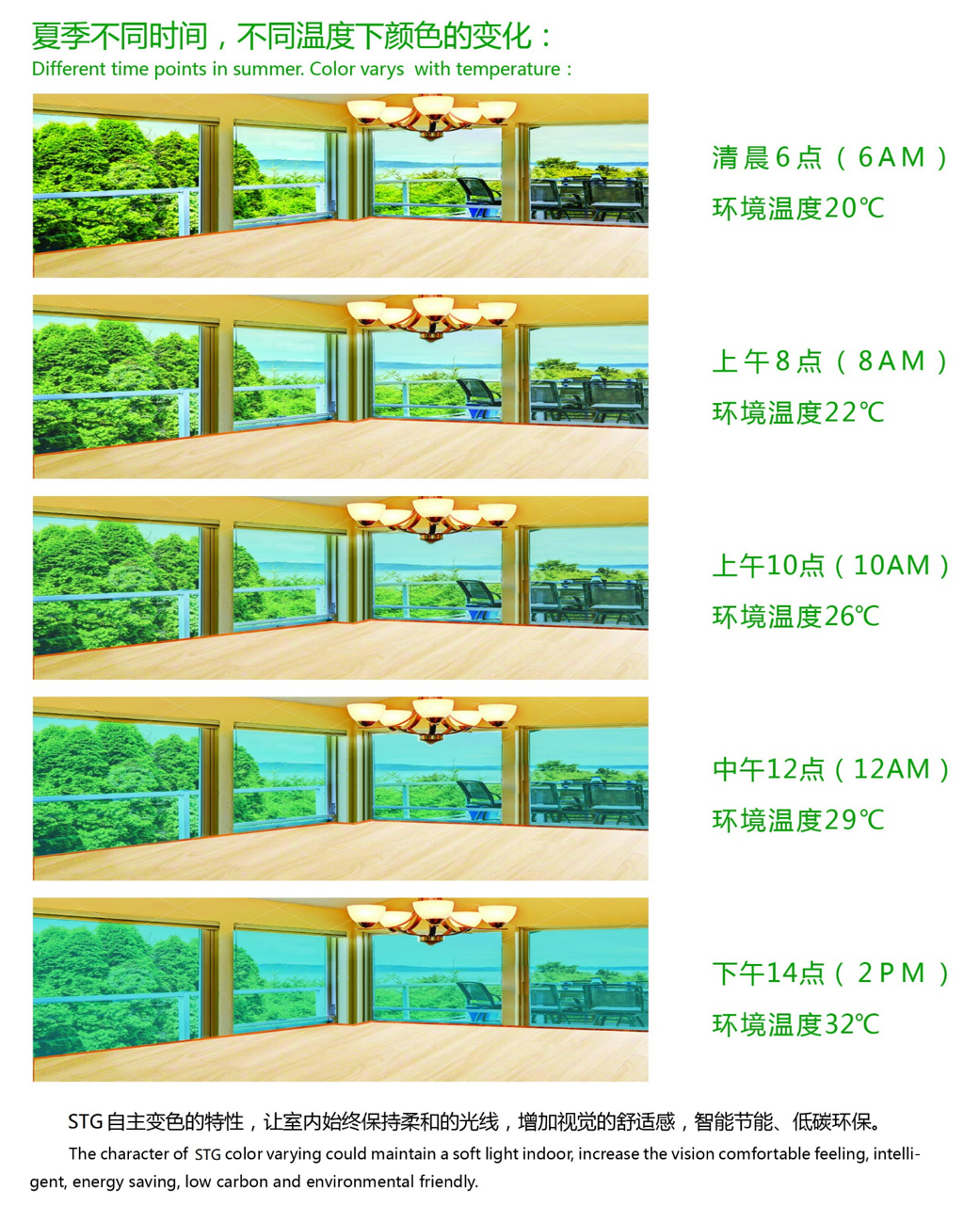

STG can block more than 99.5% of the ultraviolet rays and 85% of the infrared rays in the solar light, reduce the solar radiation heat and save energy. And it does not need any additional power supply and electronic control devices, but through the absorption of sunlight energy, Autonomous color change, intelligent shading.

STG always keeps transparent in the process of color changing and shading, and has excellent visual effect. By adjusting the visible light transmittance and shading coefficient, the glare can be reduced, the visual comfort can be increased, and the light indoor can be kept soft.

STG can be used with conventional glass deep processing configuration such as tempering, semi-tempering, hollow, vacuum, low-E, etc. to form one or more hollow or vacuum glass chambers, to provide customers with a complete set of sun-shading glass solutions.

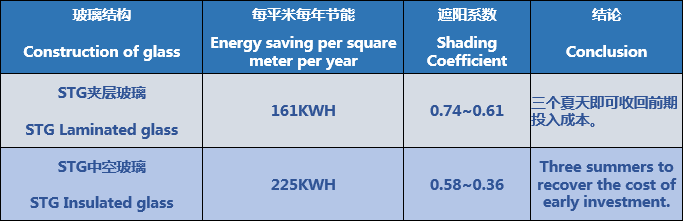

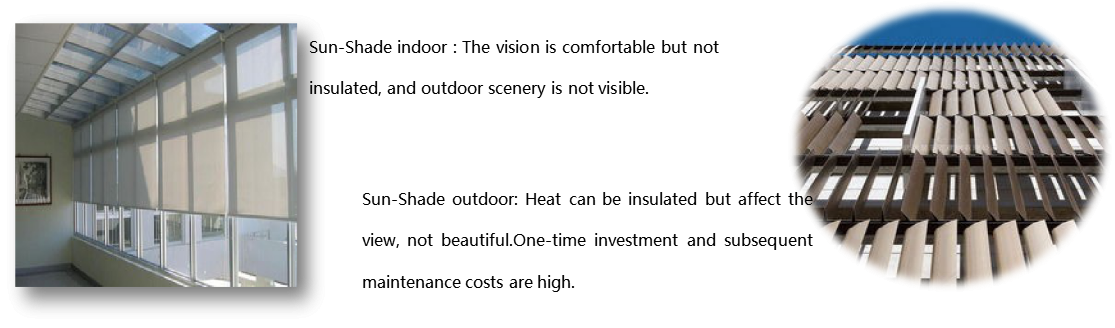

Compared with other sun-shading products, STG costs less, and with the whole life cycle of the building, there is no need for follow-up maintenance costs.

STG laminated glass is the basic unit of STI application, which meets the requirements of GB15763.3-2009 "Safety Glass for Construction Part 3: Laminated Glass".

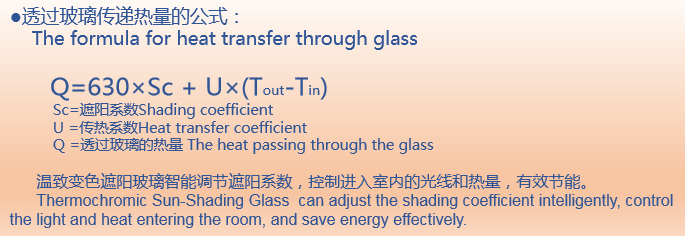

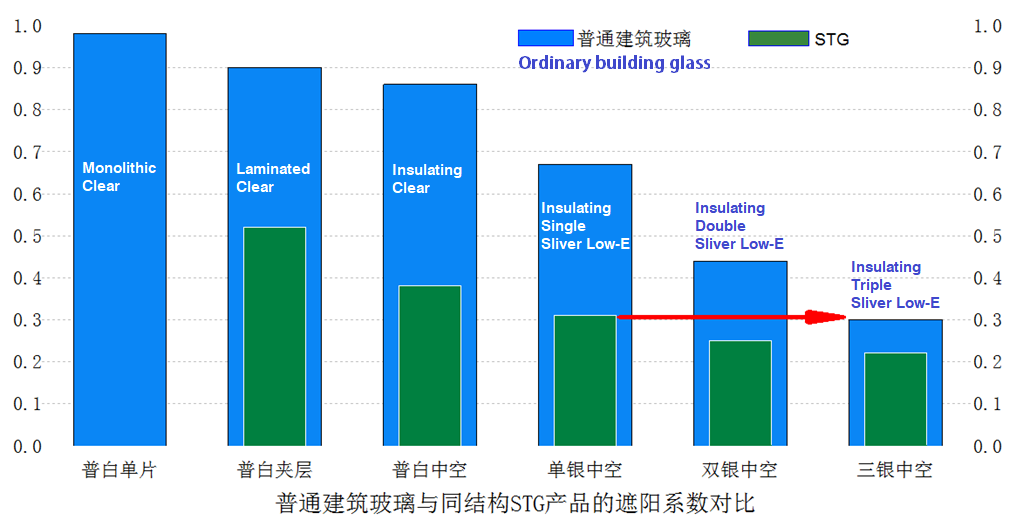

Comparison of shading coefficient betweenThermochromic Sun-shading Glass with Ordinary Glass

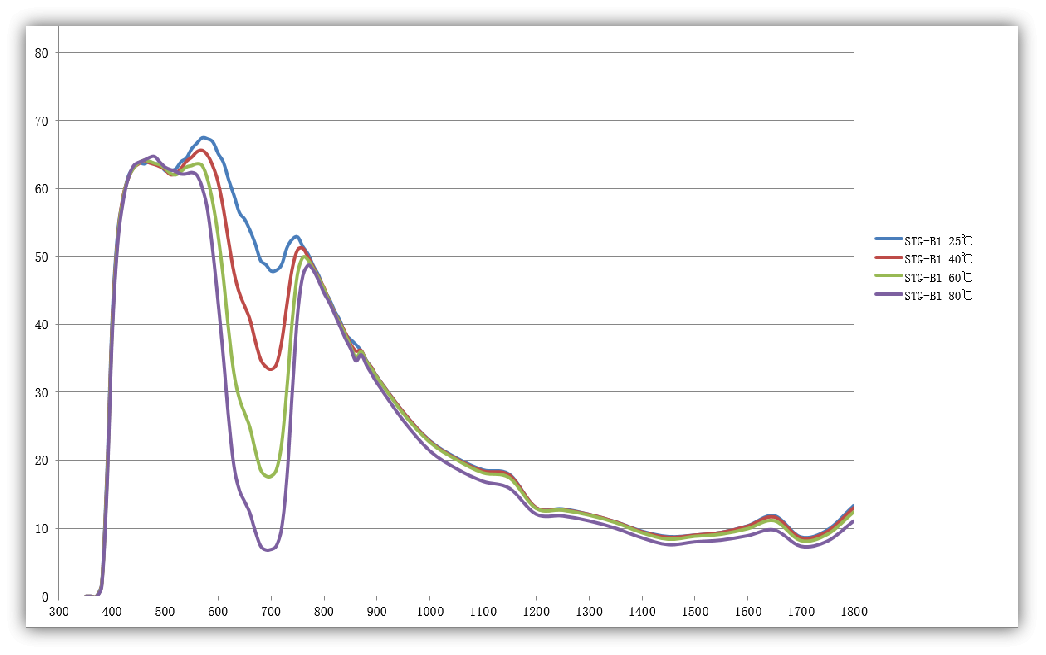

Spectral Curve of STG-B1

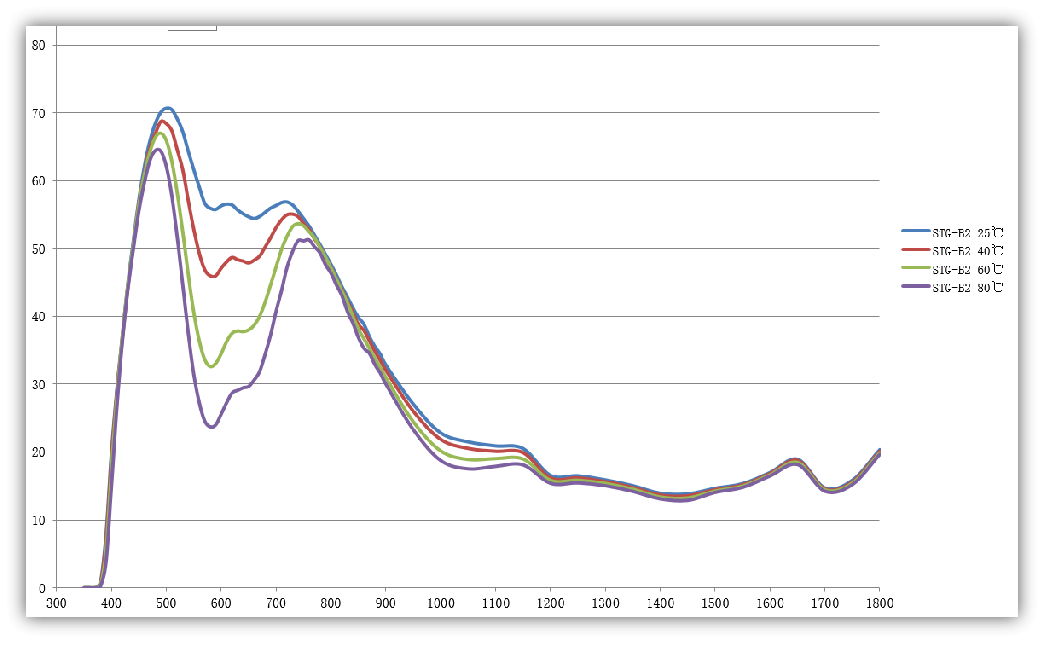

Spectral Curve of STG-B2